The Benefits of Heat Shrink Tubing for Cable Protection and Insulation

Heat shrink tubing is a versatile and essential product used in various industries, including electrical, automotive, aerospace, and telecommunications. It is a type of plastic tube that shrinks in size when heat is applied. This tubing is widely used to protect, insulate, and organize cables, wires, and other components. The process of using heat shrink tubing is straightforward, making it an ideal solution for both professionals and DIY enthusiasts. In this article, we will explore the many benefits of heat shrink tubing for cable protection and insulation and why it is a preferred choice for many applications.

What is Heat Shrink Tubing?

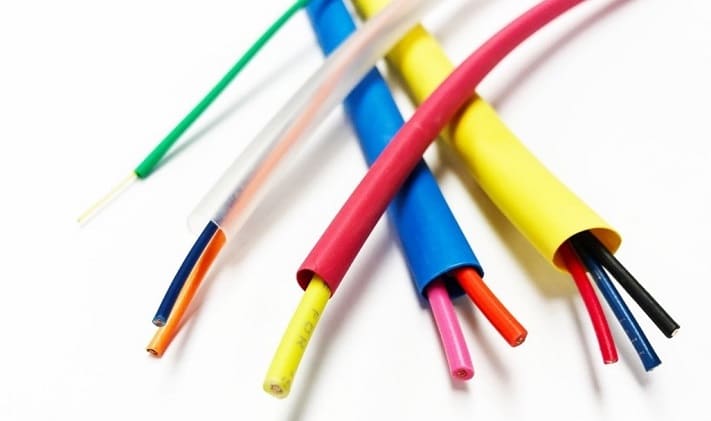

Heat shrink tubing is a protective layer made from a polymer material, usually polyolefin, which contracts when exposed to heat. The tubing comes in various sizes, thicknesses, and colours to suit different applications. It is available in rolls or precut lengths, and the shrink ratio (the degree to which it will shrink) can vary depending on the type. The most common shrink ratios are 2:1, 3:1, and 4:1, meaning the tubing will shrink to half, one-third, or one-quarter of its original size, respectively.

The process of applying heat shrink tubing is simple. First, you select the appropriate size and length of tubing and slide it over the cable, wire, or component you want to protect. Then, you use a heat gun or another heat source to apply heat evenly to the tubing. As the tubing heats up, it shrinks tightly around the object, forming a protective and insulating barrier.

Key Benefits of Heat Shrink Tubing

There are several benefits of using heat shrink tubing for cable protection and insulation. These benefits include electrical insulation, mechanical protection, environmental protection, strain relief, bundling and organizing, identification, and repair.

1. Electrical Insulation

One of the primary benefits of heat shrink tubing is its ability to provide electrical insulation. Cables and wires are often exposed to various electrical currents, and without proper insulation, they can pose serious safety hazards. Heat shrink tubing acts as a barrier between the electrical components and the external environment, reducing the risk of electrical shocks, short circuits, and fires.

By covering exposed wires and connectors with heat shrink tubing, you can ensure that the electrical connections are properly insulated and protected. This is especially important in environments where there is a high risk of electrical interference, such as in automotive or aerospace applications. The tubing’s insulating properties also help maintain signal integrity, which is crucial for data transmission in telecommunications and networking applications.

2. Mechanical Protection

Another significant benefit of heat shrink tubing is the mechanical protection it offers. Cables and wires are often subjected to physical stress, such as bending, abrasion, and impact. Over time, these stresses can cause damage to the cables, leading to malfunctions or failures. Heat shrink tubing provides a protective layer that helps absorb shocks and resist wear and tear, prolonging the lifespan of the cables.

In addition to protecting against mechanical damage, heat shrink tubing also provides a degree of flexibility, allowing the cables to bend and move without becoming damaged. This flexibility is particularly useful in applications where the cables need to be routed through tight spaces or around corners.

3. Environmental Protection

Cables and wires are often exposed to harsh environmental conditions, such as moisture, dust, chemicals, and extreme temperatures. These elements can cause corrosion, degradation, and other forms of damage to the cables. Heat shrink tubing provides a protective barrier that shields the cables from these environmental factors, ensuring their longevity and reliability.

For outdoor applications or in environments with high humidity, heat shrink tubing with adhesive lining (also known as dual-wall tubing) is particularly effective. The adhesive lining creates a watertight seal around the cables, preventing moisture from seeping in and causing corrosion. This makes heat shrink tubing an excellent choice for marine, automotive, and industrial applications where cables are exposed to water, chemicals, or other harsh conditions.

4. Strain Relief

Strain relief is an important consideration when dealing with cables and wires, especially in applications where they are subject to frequent movement or tension. Without proper strain relief, the cables can become damaged or disconnected over time. Heat shrink tubing provides an effective solution for strain relief by reinforcing the area where the cable meets the connector or termination point.

By adding heat shrink tubing to the ends of cables, you can reduce the stress on the wires and prevent them from becoming frayed or broken. This is particularly important in applications where the cables are frequently plugged in and unplugged, such as in electronic devices and equipment.

5. Bundling and Organizing

In addition to protection and insulation, heat shrink tubing is also an excellent tool for bundling and organizing cables and wires. In many applications, there are multiple cables that need to be routed together. Without proper organization, these cables can become tangled and difficult to manage. Heat shrink tubing helps keep the cables neatly bundled together, reducing clutter and making maintenance and troubleshooting easier.

Organizing cables with heat shrink tubing not only improves the aesthetics of the installation but also helps prevent accidental damage caused by tripping or snagging on loose cables. This is particularly useful in environments where safety is a priority, such as in data centres, manufacturing facilities, and automotive workshops.

6. Identification

Heat shrink tubing can also be used for identification purposes. It is available in various colours, allowing you to colour-code different cables and wires for easy identification. This is particularly useful in complex installations where there are multiple cables of the same type. By using different colours of heat shrink tubing, you can quickly and easily identify the purpose of each cable, reducing the risk of errors during installation, maintenance, or repair.

In addition to colour coding, heat shrink tubing can also be printed with labels or markings to provide additional information, such as the cable type, voltage rating, or circuit number. This makes it easier to trace cables and identify potential issues, saving time and effort during troubleshooting.

7. Repair and Maintenance

Heat shrink tubing is not only used for new installations but also for repairing and maintaining existing cables and wires. Over time, cables can become damaged due to wear and tear, environmental factors, or accidental cuts. Instead of replacing the entire cable, heat shrink tubing can be used to repair the damaged section, restoring the cable’s integrity and functionality.

To repair a damaged cable, simply cut a piece of heat shrink tubing that is slightly longer than the damaged area, slide it over the damaged section, and apply heat to shrink it in place. This creates a protective and insulating barrier that helps prevent further damage and prolongs the life of the cable.

Types of Heat Shrink Tubing

There are several types of heat shrink tubing available, each designed for specific applications and environments. Some of the most common types include:

1. Standard Polyolefin Heat Shrink Tubing

Standard polyolefin heat shrink tubing is the most widely used type of heat shrink tubing. It is flexible, flame-retardant, and provides excellent electrical insulation and mechanical protection. This type of tubing is suitable for a wide range of applications, including automotive, aerospace, and electronics.

2. Adhesive-Lined Heat Shrink Tubing

Adhesive-lined heat shrink tubing, also known as dual-wall tubing, has an inner layer of adhesive that melts and flows when heated. This creates a watertight seal around the cable, providing additional environmental protection against moisture, chemicals, and other contaminants. This type of tubing is ideal for outdoor, marine, and industrial applications where cables are exposed to harsh conditions.

3. High-Temperature Heat Shrink Tubing

High-temperature heat shrink tubing is designed to withstand extreme temperatures, making it suitable for applications in high-heat environments, such as automotive engines and industrial machinery. This type of tubing is made from materials like fluoropolymer or elastomer, which provide excellent thermal stability and resistance to chemicals and abrasion.

4. Flame-Retardant Heat Shrink Tubing

Flame-retardant heat shrink tubing is specifically designed to prevent the spread of fire in the event of a short circuit or electrical fault. This type of tubing is commonly used in applications where fire safety is a priority, such as in buildings, transportation, and industrial equipment.

5. Coloured Heat Shrink Tubing

Coloured heat shrink tubing is used for identification and colour coding of cables and wires. It is available in a wide range of colours and can be custom printed with labels or markings. This type of tubing is ideal for applications where easy identification and organization of cables are required.

Applications of Heat Shrink Tubing

Heat shrink tubing is used in a wide range of applications across various industries. Some of the most common applications include:

1. Electrical and Electronics

In the electrical and electronics industry, heat shrink tubing is used to insulate and protect wires, connectors, and components. It is also used for strain relief, bundling, and identification of cables in electronic devices, appliances, and equipment.

2. Automotive

In the automotive industry, heat shrink tubing is used to protect and insulate wiring harnesses, connectors, and sensors from heat, moisture, chemicals, and mechanical damage. It is also used for bundling and organizing cables in vehicles.

3. Aerospace

In the aerospace industry, heat shrink tubing is used to provide electrical insulation, mechanical protection, and strain relief for wiring and components in aircraft and spacecraft. It is also used for bundling and organizing cables in tight spaces.

4. Telecommunications and Networking

In telecommunications and networking, heat shrink tubing is used to insulate and protect cables, connectors, and splices. It is also used for bundling and organizing cables in data centres and networking installations.

5. Industrial and Manufacturing

In industrial and manufacturing environments, heat shrink tubing is used to protect and insulate cables, wires, and components from harsh conditions, such as moisture, chemicals, and abrasion. It is also used for strain relief, bundling, and identification of cables in machinery and equipment.

Conclusion

Heat shrink tubing is a versatile and essential solution for cable protection and insulation across various industries. Its benefits include electrical insulation, mechanical protection, environmental protection, strain relief, bundling and organizing, identification, and repair. By using heat shrink tubing, you can ensure the safety, reliability, and longevity of cables and wires in any application. Whether you are a professional or a DIY enthusiast, heat shrink tubing is a valuable tool that can help you achieve a clean, organized, and safe installation.